Need help? Call us:

0561359237

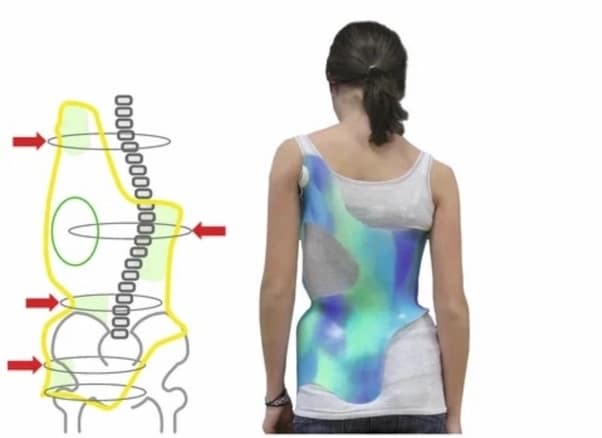

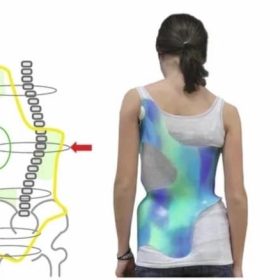

تفصيل جهاز تقويم جنف الظهر | custom made scoliosis support

Have any Questions?

Feel free to Get in touch

Creating a custom-made back brace manually involves several intricate steps to ensure a high level of craftsmanship and patient care. Here is a detailed explanation of the process, along with patient monitoring and examination:

1. Patient Assessment:

The process begins with a thorough assessment of the patient’s medical history, physical condition, and specific needs.

A medical professional, such as an orthotist or orthopedic specialist, evaluates the patient’s spinal alignment, curvature, and any existing medical conditions.

2. Measurement and Cast Taking:

Precise measurements of the patient’s torso are taken using a variety of techniques, including tape measures, calipers, and even 3D scanning technology.

A plaster or fiberglass cast is then taken of the patient’s torso to create an accurate three-dimensional model of their back.

3. Design and Fabrication:

Based on the measurements and cast, a custom design for the back brace is created using specialized software or traditional drafting techniques.

High-quality materials, often lightweight yet durable, such as thermoplastics, carbon fiber, or other composites, are selected for fabrication.

The chosen material is heated and molded over the patient’s cast to form the shape of the brace.

4. Manual Artistry:

Skilled artisans and technicians use their expertise to meticulously refine and shape the brace, ensuring a comfortable fit and optimal support.

Details like padding, straps, and closures are added, keeping patient comfort and functionality in mind.

Fine-tuning is performed to accommodate any specific anatomical requirements and address the patient’s unique spinal curvature.

5. Quality Control and Testing:

The fabricated brace undergoes rigorous quality control checks to ensure it conforms to the design specifications and meets safety standards.

Patient-specific modifications, if necessary, are made during this phase to ensure the brace fits perfectly and provides the intended support.

6. Patient Fitting and Monitoring:

The patient is fitted with the custom-made back brace, and adjustments are made as needed for comfort and fit.

Instructions on proper wearing, care, and maintenance of the brace are provided to the patient.

Regular follow-up appointments are scheduled to monitor the patient’s progress, ensure the brace is functioning effectively, and make any necessary adjustments.

7. Ongoing Patient Examination:

Periodic examinations are conducted by the medical team to evaluate the patient’s spinal alignment, mobility, and overall well-being.

Any changes in the patient’s condition or brace fit are addressed promptly, and adjustments are made as required.

8. Patient Education and Support:

Patient education plays a crucial role in the success of the back brace treatment. Patients are educated on maintaining proper posture, exercising, and following prescribed guidelines.

The medical team provides ongoing support and guidance to ensure the patient’s comfort, compliance, and progress throughout the treatment period.

In conclusion, the meticulous process of manually crafting a custom back brace involves a combination of medical expertise, skilled craftsmanship, and continuous patient monitoring to provide optimal spinal support and improve the patient’s quality of life